Previous

Next

About Castmaster Group

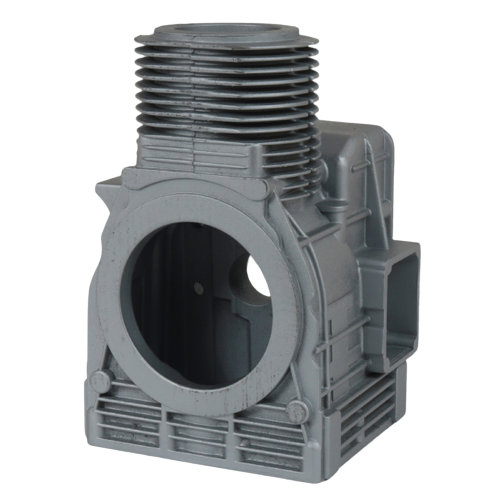

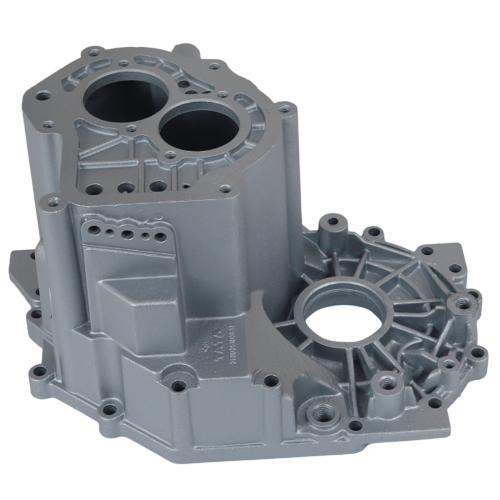

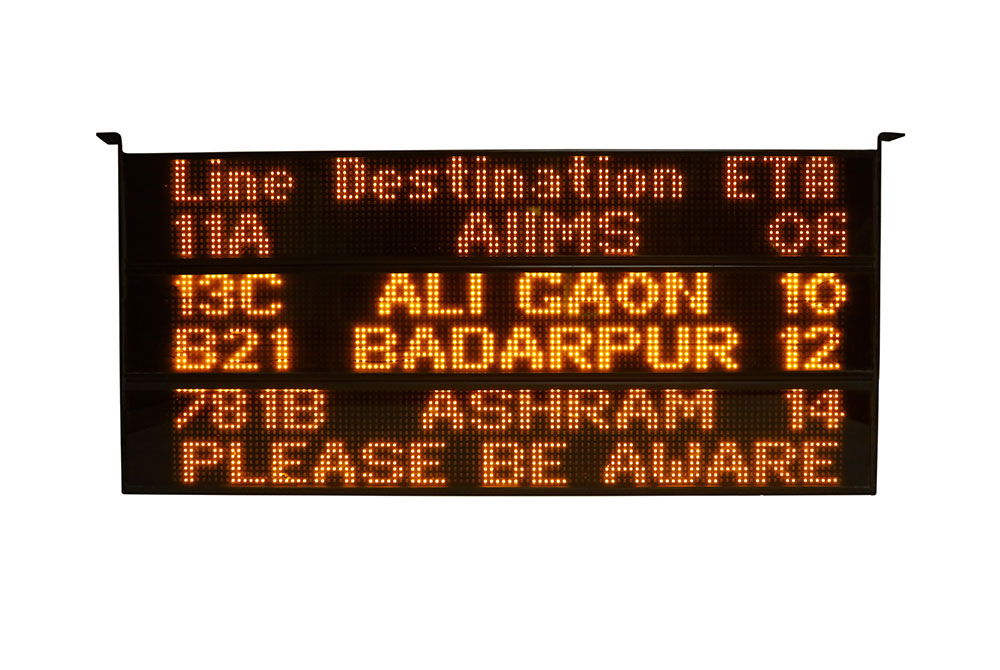

We at CASTMASTER Group are setting standards in India through innovative production techniques and stringent quality control in the die casting technology for the processing of Aluminium alloys.

Our partnership with you, helps optimize profitability through consistent quality and timely deliveries. Organizations demanding high precision and complete reliability have found us to be ideal partners.

Our technical excellence from design conceptualization to die making and from molten metal to machining of the finished castings is placed at your disposal in meeting your rigorous demands. Today, components cast by us are also exported to a number of countries for use in highly sophisticated industries.

0

+

Years Of Experience

0

+

Manufacturing Plants